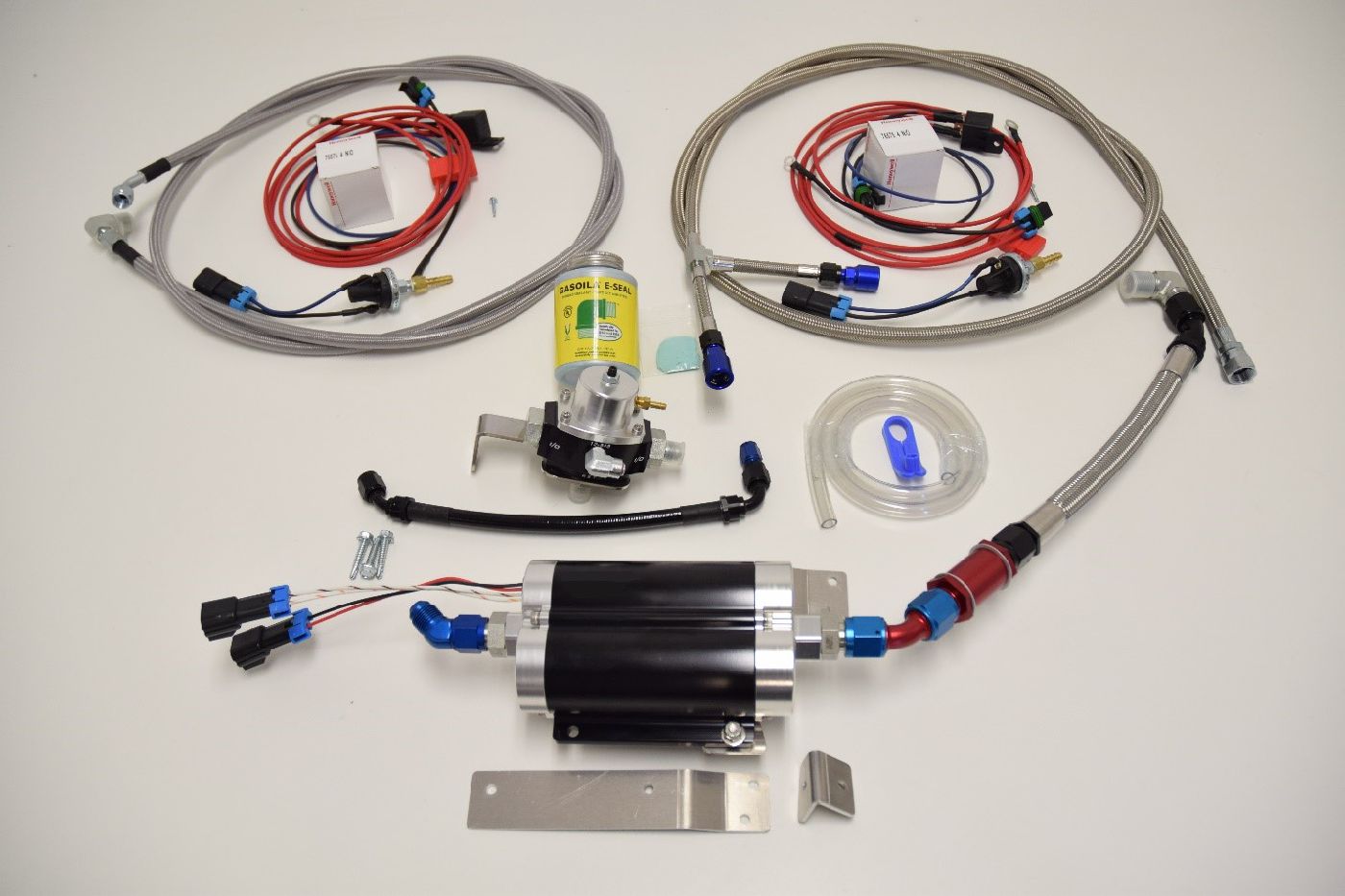

There is absolutely no fabrication of lines and fittings needed.

Each hose is pressure checked at our facility before shipment.

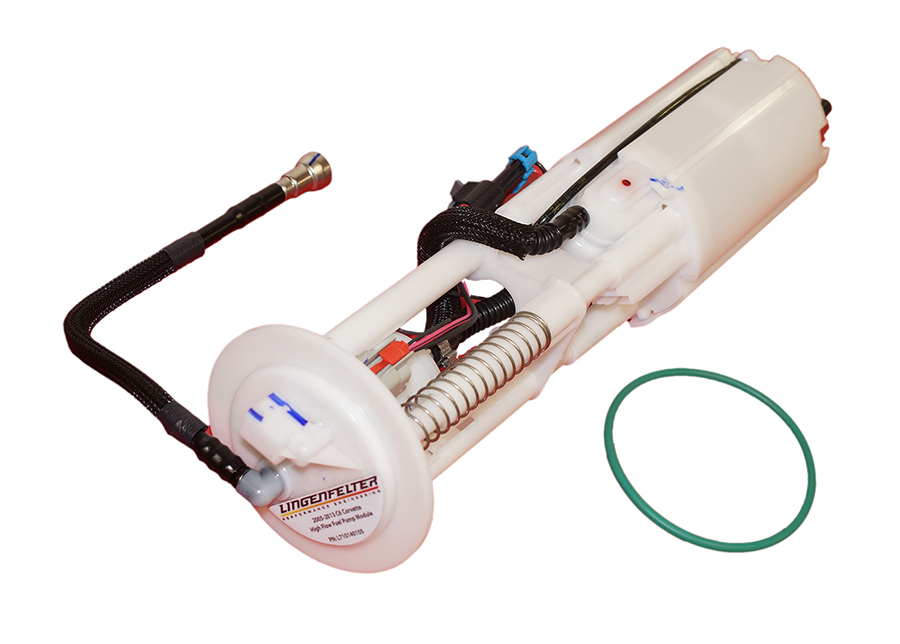

This can save 10 hours or more in labor costs alone. Our systems do not require dropping the tanks and complete drivetrain and will supply enough fuel for your 600 to over 1000 RWHP project. The deterioration of a fuel pump due to age as well as the extra demands on the fuel system due to performance enhancements mean that replacing your factory pump should be one of the first modifications for your performance car.We designed our secondary fuel system for both early and late models with ease of installation in mind. These Walbro fuel pumps have become the industry standard for fuel pump upgrades on performance vehicles. We have even used two or three of these pumps set up in parallel drawing from a single surge tank to support applications making in excess of 1000hp. If you are building a high-performance fuel-injected machine and require an external fuel pump (or several) then these are a great option without spending a fortune. This can be used by itself with a fuel cell (or suitable fuel tank) or in series with other fuel pumps or most commonly it is used on high performance applications with a fuel surge tank (note that applications with a surge tank also require a low pressure lift pump to fill the surge tank).

This is a universal in-line EFI fuel pump which mounts outside of your fuel tank. You can either choose 5/16″ or 3/8″ push on hose barb fittings or AN-6 (anodised aluminium) or AN-8 (stainless steel) fittings as commonly used on applications with anodised fittings and braided stainless fuel lines.

We also offer this pump with optional fittings.

0 kommentar(er)

0 kommentar(er)